1、Introduction

With the continuous advancement of dental restoration technology, the variety of dental materials has also gradually increased. Ceramics have been widely used in various fields of dental restorative materials due to their excellent mechanical properties, biocompatibility, and structural stability. Depending on the type of ceramics, all-ceramic dental materials include pressed ceramics, glass ceramics, and zirconia ceramics. Pressed ceramics and glass ceramics have relatively low strength. In contrast, zirconia ceramics exhibit higher mechanical properties due to phase transformation toughening between the monoclinic and tetragonal phases, making them more suitable for dental applications. Additionally, zirconia offers several advantages: structural stability, non-reactivity in the oral environment, excellent biocompatibility, and high translucency. Therefore, over 95% of all-ceramic crowns and bridges are made of zirconia ceramics.

2 、Overview of Zirconia Ceramic Properties

2.1 Basic Properties of Zirconia Ceramics

High-purity zirconia powder is white, and zirconia ceramics appear chalky white. The molecular weight is 123.223 g/mol, density 5.85 g/cm³, and melting point 2715°C. Zirconia has three crystalline structures: monoclinic, tetragonal, and cubic. These structures exhibit different forms at various melting points and can transition under certain temperature conditions. The transition temperature between the monoclinic and tetragonal phases is around 1150°C, and between the tetragonal and cubic phases is about 2370°C. The martensitic phase transformation occurs during the transition from tetragonal zirconia to monoclinic zirconia, accompanied by volume expansion.

2.2 Toughening of Zirconia Ceramics

Compared to metals, ceramic materials generally have lower fracture toughness by 1-2 orders of magnitude. Zirconia ceramics can enhance their fracture toughness through various toughening mechanisms, including stress-induced phase transformation, microcrack toughening, crack deflection, branching and bridging, whisker toughening, dispersion toughening, fine-grain strengthening, and fiber toughening. In practical applications, the improvement in zirconia ceramic toughness often results from the combined effect of multiple toughening mechanisms. The most commonly used methods in laboratory measurements of zirconia ceramic fracture toughness are the single-edge notched beam method and the indentation method.

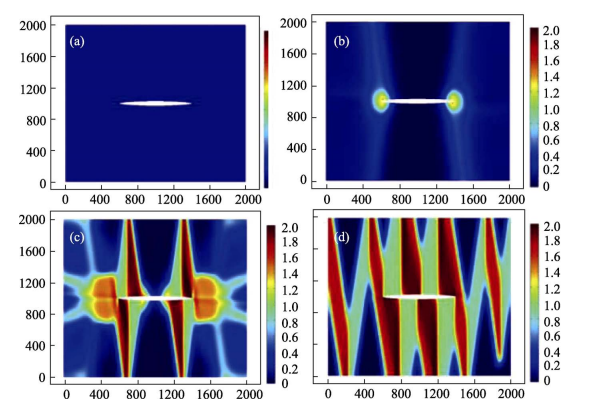

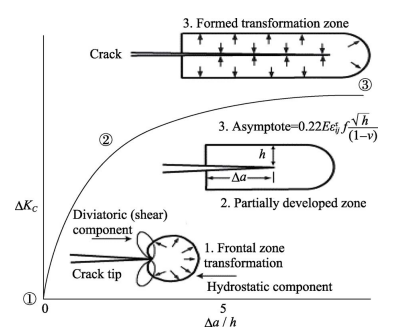

Research on the toughness of zirconia ceramics began in the 1950s. After the discovery of phase transformation phenomena in 1975, some researchers proposed that stress-induced phase transformation toughening is due to the external stress-induced crack formation in zirconia ceramics. The stress at the crack tip can induce the t→

m martensitic phase transformation, and the volume expansion of the transformed grains inhibits crack propagation, thereby enhancing the material’s toughness. However, during the initial phase transformation stage, the expansion deformation within the 120

°

angle at the crack tip can reduce the toughness of zirconia. Subsequently, volume expansion inhibits crack propagation, rapidly increasing toughness. When the crack extends to 5-10h, the growth in fracture toughness slows down.

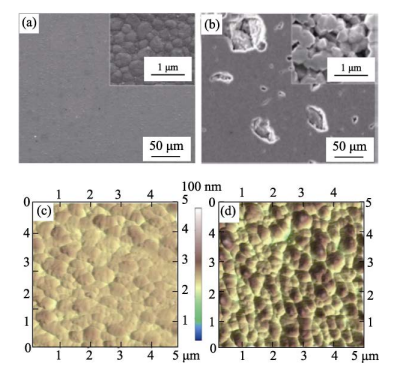

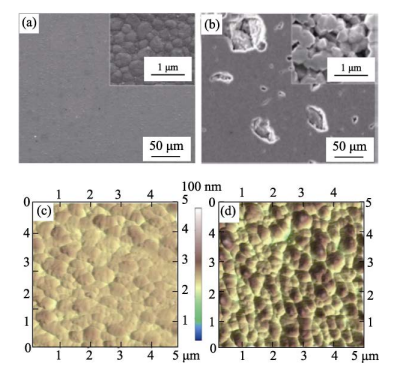

2.3 Low-Temperature Degradation of Zirconia Ceramics

In low-temperature and humid environments, the t→m phase transformation aging of zirconia is essentially a martensitic transformation: a non-thermodynamic, diffusionless change in crystal structure. Low-temperature aging first induces t→m phase transformation on the material’s surface, causing volume expansion, surface protrusions, microcracks, and aesthetic degradation. Subsequently, water molecules penetrate the material’s interior along the microcracks, triggering internal t→m phase transformation, leading to macrocrack formation and a decline in mechanical properties, potentially causing sudden failure. Extensive experimental studies have identified four main characteristics of low-temperature aging:

1) Low-temperature aging is a non-thermal, autocatalytic process, with t→m phase transformation aging occurring through the nucleation and growth (N-G) mechanism of the m phase.

2) Aging conditions (temperature, time, water or steam) accelerate zirconia aging.

3) Aging increases the m phase content, reduces toughness, and degrades aesthetics.

4) Stabilizer content and grain size directly impact zirconia’s resistance to low-temperature aging.

3、Preparation Techniques of Dental Zirconia Ceramics

Currently, the preparation techniques for dental zirconia ceramics can be categorized into two main types: removing excess material from a bulk form and directly forming the shape by adding material.

3.1 CAD/CAM Milling Technology

With the rise of computer-aided design/manufacturing (CAD/CAM) technology, forming dental restorations has become more convenient and efficient, significantly meeting market demands. The specific process involves traditional impression and model making of the patient’s damaged area, followed by scanning the model and using CAD/CAM technology for milling and polishing the block material to obtain the desired shape of the restoration. Depending on the densification of the block material before machining, there are two types: hard machining and soft machining. Hard machining involves fully sintering the ceramic material to achieve 99% density, followed by machining the block into shape. Soft machining involves cold isostatic pressing of zirconia powder into blocks, pre-sintering, machining into shape, and final sintering.

3.2 3D Printing Technology

In dentistry, 3D printing technology has been employed to create dental models, meeting patients’ personalized needs and improving production efficiency. Various forms of 3D printing technologies have developed, including inkjet printing, selective laser sintering, stereolithography, and extrusion freeforming. 3D printing is more suitable for producing crowns, bridges, implants, and prosthetics with complex curved structures. Currently, 3D printed bioceramic materials are still in the early stages, with most research focusing on in vitro experiments, and no clinical trials have been reported. Technical issues regarding the density, size, porosity, and surface strength of all-ceramic restorations and frameworks remain unresolved.

4、Advantages of Zirconia Ceramics in Dental Implants

Due to its high corrosion resistance and excellent mechanical properties, zirconia is considered an ideal ceramic material for dental restorations. Compared to other implants, zirconia implants offer significant advantages:

1. Hygiene: Research indicates that zirconia implants, due to their poor surface wettability, reduce bacterial adhesion and biofilm formation. Compared to titanium implants, zirconia retains less dental plaque on the surface, lowering the risk of inflammation in surrounding tissues, thereby promoting healthier gingival conditions.

2. Aesthetics: Zirconia’s bright white color closely resembles natural teeth, making it a more natural-looking replacement material than metal implants. It also eliminates the darkening of the gum line caused by metal implants, meeting aesthetic demands.

3. Strength: Zirconia implants have mechanical strength comparable to titanium implants, along with high fracture toughness and wear resistance, meeting the strength requirements for dental implants.

4. Biocompatibility: As a bioinert material, zirconia exhibits excellent biocompatibility, causing no toxicity, allergies, or inflammatory reactions in the body.

5. Osseointegration: Studies show that zirconia implants achieve bone contact levels similar to titanium implants, indicating stable bone integration.

6. Chemical Stability: Zirconia’s stable chemical properties and high corrosion resistance ensure long-term stability in the oral environment.

5、Conclusion

In recent years, zirconia has become a research hotspot for dental restorations due to its excellent aesthetic and mechanical properties, highlighting its significant potential in dental restoration. Given the increasing aging population and the growing desire for a better quality of life, zirconia’s anti-aging performance improvements and future functional health requirements will see broader applications in biomedical fields.

Leave a Reply