With advancements and growing popularity in digital clinical technology in dentistry, the quality and efficiency of dental care have been greatly enhanced. This technology reduces the reliance on clinical experience and aids young dentists in developing their skills, promoting standardized treatment quality across various regions.

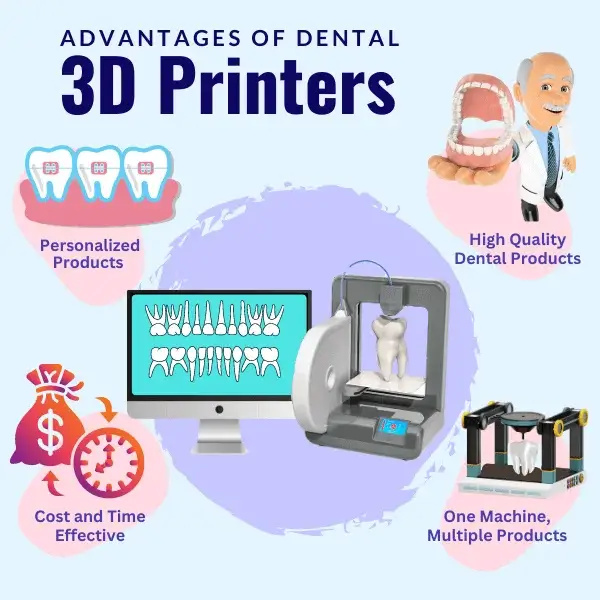

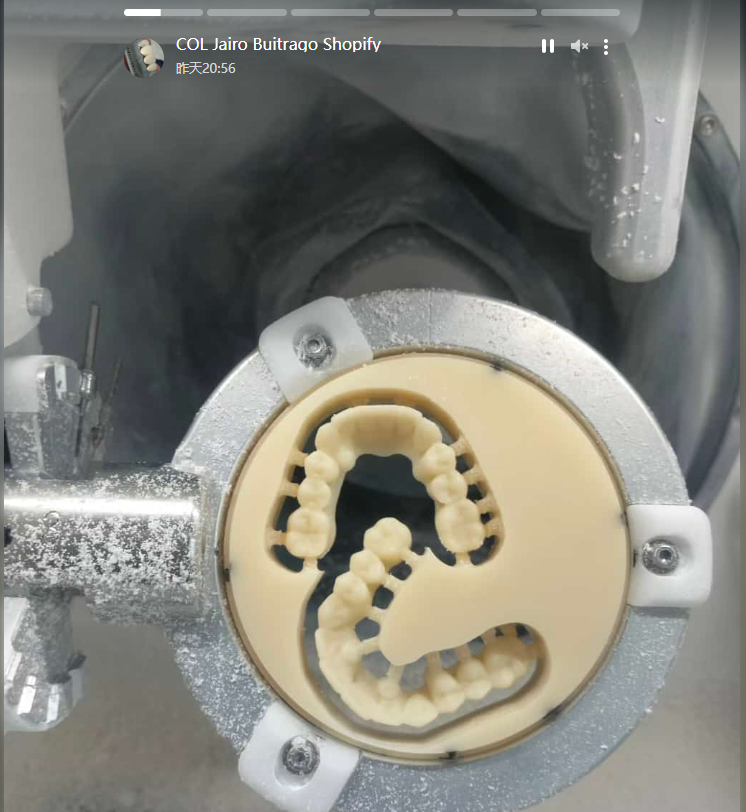

Digital technologies now enable chairside dental procedures, reducing patient visits and enhancing the overall experience. As digital technology integrates further with dentistry, the use of CNC milling and 3D printing to create dental prosthetics and auxiliary devices has become a significant application area. This has led to the development of new “digital dental materials,” drawing considerable attention and becoming a crucial focus in dental material science.

**Types and Processing of Oral Materials**

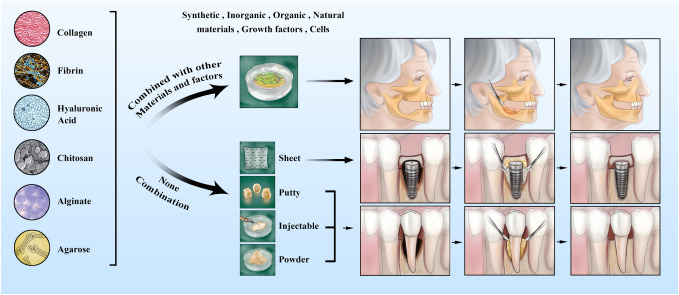

Dental materials can be categorized based on their form: non-shaped materials (e.g., impression materials, filling materials, bone powders, adhesives), pre-shaped materials (e.g., orthodontic brackets, implants, artificial teeth), and custom-shaped materials (including casting, manual bending, milling, and 3D printing). Materials related to digital dentistry typically involve custom-shaped materials, specifically CNC milling (subtractive manufacturing) and 3D printing (additive manufacturing) materials, which can be further divided into metallic, resin-based (polymeric), and ceramic materials.

**Industrial and 3D Printing Advantages**

Pre-made industrial materials (blocks, discs) are typically more uniform and mechanically superior to those made through casting. 3D printing offers high material efficiency and is environmentally friendly, suitable for complex shapes. It matches the mechanical properties of cast items and has become a key technology in manufacturing.

**Digital Ceramic Materials**

Primarily used in milling and grinding processes, digital ceramics include feldspar, glass ceramics, alumina, zirconia, and glass-infiltrated composites. Feldspar and glass ceramics, being glass-based, offer good translucency and aesthetics, mimicking the optical properties of enamel and dentin, making them ideal for anterior aesthetic restorations. Pre-colored ceramic blocks allow the creation of anatomically complete restorations, simplifying or replacing traditional veneering processes. However, their low fracture toughness requires strict adherence to clinical indications.

Zirconia, a highly dense polycrystalline metal oxide ceramic, has seen rapid development. It can be processed into full-contour zirconia restorations, known for high strength and the ability to adjust translucency via yttrium content. Zirconia is also used for implants and abutments to improve aesthetics over titanium.

**Digital Composite Resin Materials**

Composite resins are enhanced polymers composed of organic resin and inorganic fillers. The inclusion of nano-ceramic fillers has significantly improved their properties, making them comparable to glass ceramics. Resin-based ceramics are categorized by either adding inorganic fillers to a resin matrix or incorporating resin into a ceramic network. They offer excellent load capacity, fatigue resistance, and cutting performance, aligning closely with the mechanical properties of dentin and composite resins.

**Digital Metal Materials**

Dental metals include nickel-chromium, cobalt-chromium, gold, titanium alloys, and pure titanium. CNC milling of metals is well-established, with high precision and complexity capabilities, making it suitable for customized implant abutments, denture frameworks, and orthodontic appliances. Metal 3D printing, particularly selective laser melting (SLM), has shown great promise. It’s efficient, precise, stable, and economically advantageous, supporting batch production, such as over 200 metal crowns in one cycle.

**Other Digital Materials**

Traditional wax materials can be customized for machining, or mixed with photopolymerizable liquids for 3D printing, useful for diagnostic models or casting. Polyether ether ketone (PEEK) is a novel material in dentistry known for its high temperature resistance, corrosion resistance, and excellent machinability, also compatible with 3D printing. It’s used for dentures, frameworks, and surgical guides.

**Future Outlook**

Appropriate dental material selection is crucial for the aesthetic and long-term success of treatments. Dentists should understand these materials’ mechanical properties and digital processing characteristics to optimize clinical outcomes. Advances in 3D printing and personalized materials, such as bioactive and 4D biomaterials, promise to drive the future of dental materials towards greater aesthetics, biomimicry, and functional gradients.

Leave a Reply